What is OMS

Modern trading business requires new approaches for management. Client will not wait, which means he/she needs to be offered the fastest and most convenient ordering service. The solution is to implement OMS.

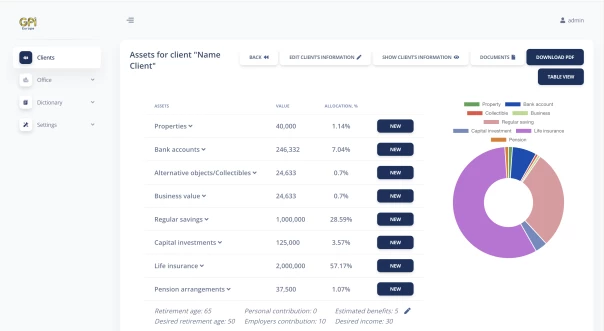

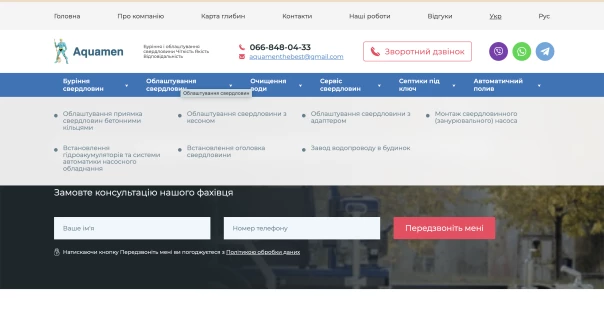

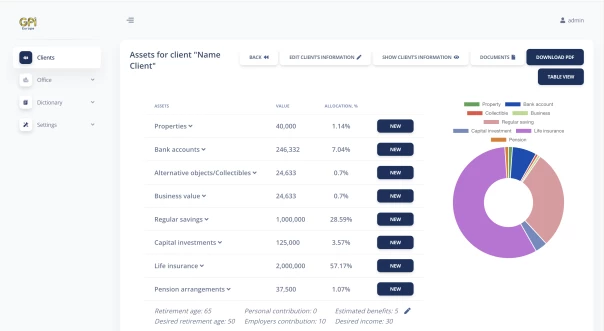

CRM System Replatforming for Financial Consultants

More about the serviceCRM System Development

We provide a full range of services for the development and support of online stores, informational websites, CRM/ERP systems, and SEO optimization — from creating technical specifications and prototyping to configuration, launch, and ensuring the quality and stability of your product.

Development and Support of ERP for a Tank Washing and Repair Depot

More about the serviceERP System Development

We develop custom ERP systems — comprehensive solutions for automating and integrating key business processes (finance management, HR, production, supply chain, sales, and more). We provide a full cycle of services: needs analysis and technical specification development, architecture design, system development and integration with existing solutions, implementation with staff training, as well as technical support and regular updates.

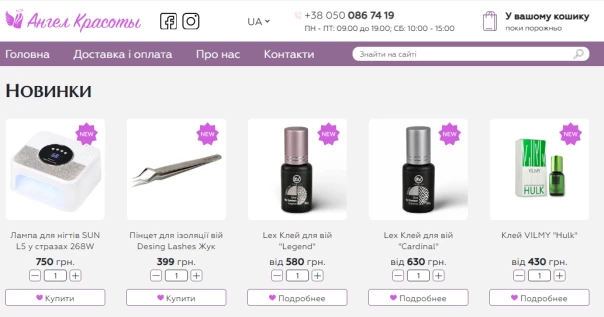

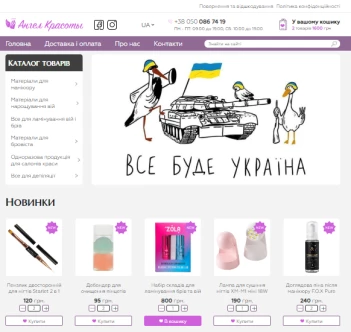

Online stores for beauty professionals.

More about the serviceOnline Store Development

Online store development is a comprehensive process of creating an e‑commerce platform tailored to all client requirements — from preparing technical specifications, prototyping, and design to implementing the website and admin panel, testing, content integration, and ongoing support. This ensures a convenient UX for customers and seamless store operation.

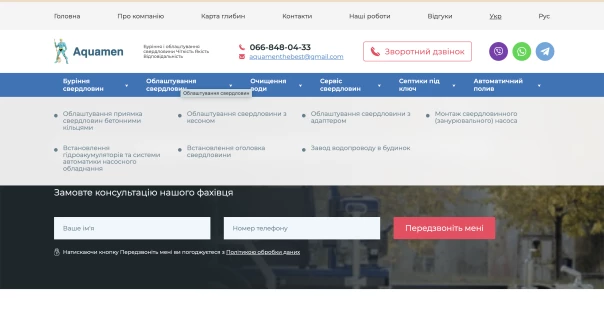

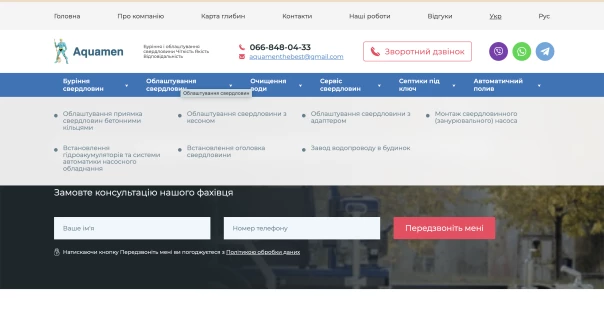

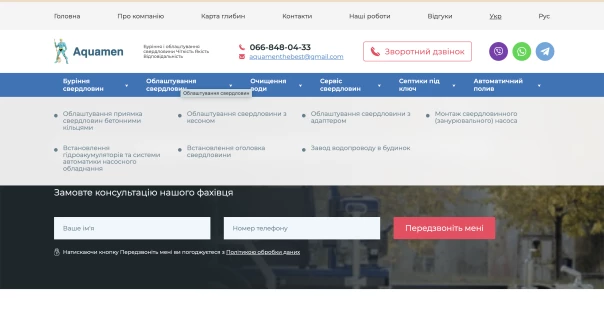

Development of an SEO-optimized informational website for a well drilling company.

More about the serviceDevelopment of informational websites

The development of an informational website is essential for those who aim to showcase their activities online and attract new clients: a modern business card website allows for flexible content updates through an admin panel, displays news and links to social media, and is optimized for search engines, retaining existing audiences and increasing brand trust.

SEO website promotion — boosting visibility and attracting clients from search

We help businesses receive a stable flow of clients from Google. SEO promotion is not just about keywords, but a comprehensive set of work — from technical optimization and content to analytics and link-building.

We create business websites for companies of any size

We develop modern business websites that help present your company, attract new clients, and increase brand trust. These can be landing pages, corporate websites, or multi-page portals with additional functionality.

Content creation — texts, visuals, and videos for your business

We combine the power of artificial intelligence with the expertise of our copywriters, designers, and video editors. We create texts, visuals, and videos that help your brand look professional, communicate effectively, and attract customers.

We create convenient business card websites for companies of any scale

We develop business card websites that help quickly present services, increase recognition, and attract clients. Such websites are ideal for specialists, small companies, or brands that require a compact yet professional online presence.

Content management — professional content creation and support for your website

We take care of all tasks related to content creation, updates, and website structure. Content management is a set of services that includes adding texts, photos, products, news, SEO elements, and keeping your website up to date.

Server administration — stable performance, security, and productivity for your business

We provide full technical server administration to ensure your websites and services run reliably 24/7. Our team has been working for years with Hetzner — one of the most reliable European data centers. We know how to properly configure, optimize, and maintain the infrastructure for your project.

We create intelligent chatbots for Telegram, Viber, WhatsApp, and websites

We develop chatbots that automate customer communication, sales, and technical support. Bots help respond faster, collect requests, accept payments, and operate 24/7 without days off.

Screenshot of the warehouse management module

View Case

ERP system for managing a tank container cleaning and repair station, built on Symfony and deployed on Linux Ubuntu with MySQL for reliability and scalability. The solution includes an administrative panel and a client portal with 49 modules for managing clients, orders, finances, calendar, inventory, and reporting, with capabilities for automatic PDF invoice generation, notifications, and data export to accounting software for complete business process digitalization.

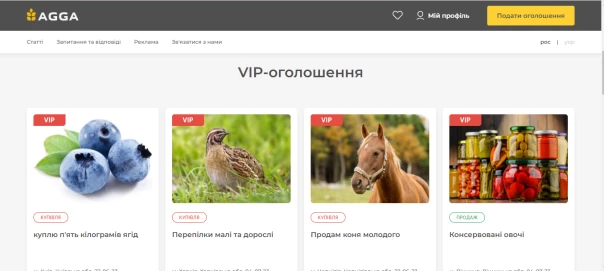

Homepage of the website, VIP announcements block

View Case

A platform for posting announcements in the agricultural sector, connecting farmers, suppliers, and buyers to streamline the buying and selling of agricultural goods and services with increased market transparency and reduced search costs. The system includes an admin panel for moderating announcements, managing content, and analytics, as well as a seller's personal account with the ability to publish and manage announcements and transaction history.

Homepage of the website, VIP announcements block

View Case

A CRM system for a financial consulting company, developed as a custom solution instead of a SaaS product to automate document management and enhance client interaction through admin and client interfaces, with capabilities to manage assets, users, calendars, and dictionaries, generate PDF reports, and synchronize events with Outlook. The project is built on Symfony with PHP 8.3, deployed on Ubuntu 22.04 with a MySQL 8.0 database to ensure system reliability, security, and scalability.

Main Menu of the Project

View Case

Informational website Aquamen for water well drilling services, built with a user‑friendly admin panel for managing users, content blocks, and a feedback module. It supports SEO features (automatic sitemap, no‑index/no‑follow) and sends notifications about new requests via a Telegram bot.

Home Page, Main Menu

View Case

Online store for beauty professionals, developed on Symfony 6.4 and PHP 8.3, deployed on an Ubuntu 22.04 server with a MySQL 8.0 database. It features an intuitive client interface with a product catalog, shopping cart, and order checkout, along with a powerful admin panel for managing products, categories, brands, users, orders, and SEO optimization. The system supports data export and automatic generation of PDF invoices and reports.

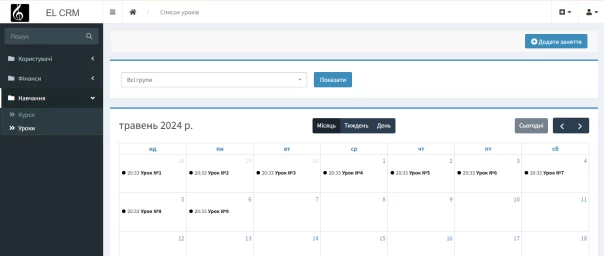

Website Home Page, Users, Finance, Learning

View Case

CRM system for a foreign language school designed to efficiently manage student relationships: it enables storing and structuring personal data, course history, and communication records, while automating registration, payment, and class scheduling processes through three key modules — Users, Finance, and Learning.

Website Home Page, Users, Finance, Learning

View Case

A custom CRM system for a service business in the truck detailing industry. The solution enables centralized management of clients, services, orders, payments, and staff, automates payroll calculations, and provides detailed business analytics.

Website Home Page, Users, Finance, Learning

View Case

A Telegram bot with an administrative panel was developed for the client, allowing for the automation of order intake, product catalog management, and request processing without operator involvement. The solution is designed for fast customer service and easy management for the business.

Website Home Page, Users, Finance, Learning

View Case

A fast start for your service business: an intuitive client-facing website, easy booking management, and simple service control via the admin panel.

Website Home Page, Users, Finance, Learning

View Case

An interactive web calculator for furniture businesses that allows customers to configure products independently, receive an accurate cost calculation, and generate a detailed PDF report with drawings.

Website Home Page, Users, Finance, Learning

View Case

A ready-made solution for launching an expert business focused on selling services and products. The website structure is adapted for scalable growth, easy content management, and fast project launch.

Modern business is guided by principles that significantly differ from traditional, familiar models. Digitalization and automation of processes are in trend. This is especially true for the logistics industry. Many companies still practice manual warehousing, but the quality of such businesses differs from that of more modern market players. The key to their efficiency is a warehouse management system (WMS).

Warehouse Management System or WMS is a system for managing the processes of a warehouse, logistics center, and similar facilities that provides full automation of workflow. Depending on the capabilities of the software and hardware, the complex is capable of performing a number of tasks automatically: receiving goods, taking inventory, planning storage and shipping, etc.

A WMS system is a reliable solution for warehouse management. Especially in large companies. It is almost impossible to imagine a modern business without WMS automation. It greatly simplifies the management of such a business and improves the efficiency of all internal processes of the company.

WMS systems differ in their functionality depending on the level of software. Basic versions are the most common. Such software controls the process of receiving, picking, and shipping an object from a warehouse. More complex warehouse management systems can control the work of not just one room, but several at once.

The complex is able to analyze and control the main points of warehouse management in detail. These include:

monitoring of storage locations to ensure normal unloading of products - goods cannot be stored anywhere, there is a certain scheme for their placement, which is what the system does;

The internal operations of a logistics center are well-established when each element of the center performs its role accurately. WMS is a control tool and a reliable assistant in this task.

A warehouse can be considered a living organism that works thanks to the coordinated work of each of its parts. WMS systems help:

The logistics business is closely related to time, which employees do not have much of. WMS warehouse management systems are capable of monitoring hundreds (even thousands) of warehouse operation points, which significantly reduces the likelihood of critical staff errors.

A modern warehouse consists of thousands of documents, each of which has equal value. As a rule, this work is assigned to human resources.

Modern warehouses actively use such management systems. WMS reduces the amount of paperwork by controlling document flow processes. Every action, from receiving and packing goods to shipping them, is accompanied by an electronic system.

The software has capabilities for both operational resource management and warehouse scheduling. For example, WMS systems can be configured to repeat a specific operation according to a given schedule. Owners can flexibly adjust their business to specific situations: workload, arrival of special goods, priority of a particular customer, and many other parameters.

WMS systems are not just a program that is installed on a computer. It is a complex that is customized (or developed) for specific business tasks.

A WMS warehouse management system consists of an IT and hardware complex. The latter includes:

The amount of hardware and software directly depends on the activity and scale of the warehouse center.

WMS systems are divided into several types:

Small centers can get by with entry-level software. However, large businesses require customized solutions. The software allows you to solve the issue of warehouse automation of any level. Such software is developed with the prospect of business development, expansion, and scaling.

Modern trading business requires new approaches for management. Client will not wait, which means he/she needs to be offered the fastest and most convenient ordering service. The solution is to implement OMS.

E-commerce is actively developing, and each company’s purpose – is to maximize audience reach. However, how can you put your business in order if the number of SKUs is measured in tens, hundreds of thousands and more? PIM – is a powerful solution for such tasks.

WMS systems for the logistics business. Features of using WMS in Ukraine – the most common functionality. Top warehouse management systems in Ukraine.

Fill out the form to receive a free consultation